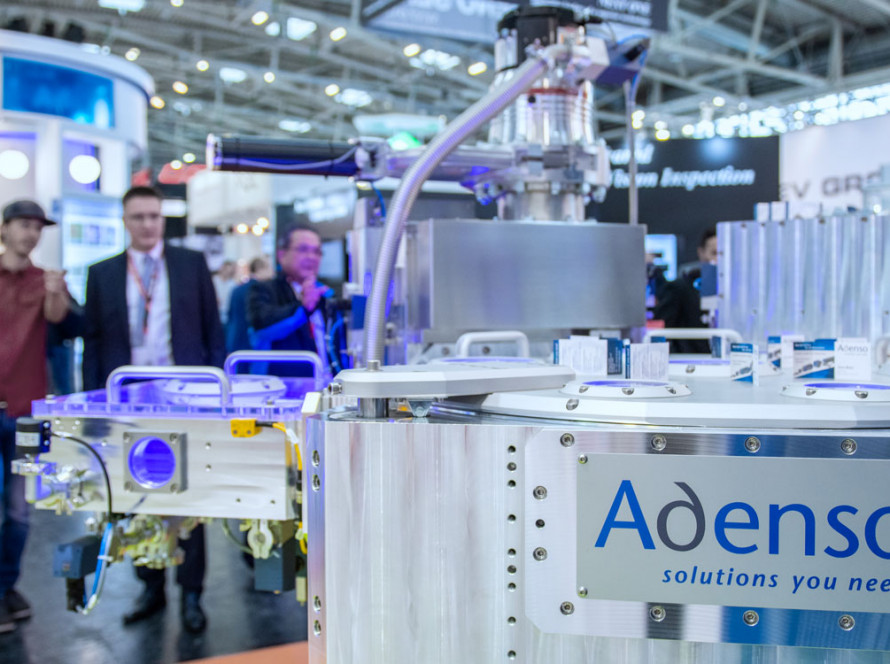

the VSC200 vacuum suitcase of Adenso

Adenso extends its VAC.LOADPORT product portfolio for the VAC.ROBOTICS segment to include the VSC200 vacuum suitcase. The first transport technology in and for vacuum process systems – compact, lightweight and easy to handle.

While retaining the respective necessary vacuum environment, all substrates – round, angular, narrow wafers or higher carriers – are loaded into the vacuum-tight, lockable VAC.SUITCASE, uncoupled und transported. For the first time ever, it enables the connection of spatially separated systems from room to room or worldwide.

Why are unfinished semiconductor substrates sent?

Networked working makes information available worldwide – physical resources, however, are non-transported and are only available to a limited extent. If research teams are now offered the possibility of distributing their substrates worldwide without breaking the vacuum chain and docking them onto other process systems, then the possibilities are suddenly expanded. With immediate effect. all worldwide available resources can be included for the development of the latest technologies. The limited equipment on site is thus no longer decisive for possibilities and success. New research approaches and ideas can therefore be implemented and evaluated in the shortest time without budget limits. Moreover, development time is also a significant cost factor.

For the first time ever, research groups are thus also able to market existing technology worldwide as a service – which leads to higher system utilisation and not least is a good message for our environment.

Why is a vacuum environment so important for transport?

The manufacture of electronic components requires hundreds of process steps – virtually all of which are technologically highly sophisticated and only successful under the exclusion of ambient air, as oxygen and moisture irreparably damage the sensitive layers. Adenso customers network research teams in the whole world by handing over processed wafers to another research unit with the relevant required equipment (for analysis purposes or for further processing).

Worldwide VAC docking – how can that work?

Worldwide established interface standards exist in the semiconductor and vacuum industry. The VAT gate valves that meet the SEMI requirements have established themselves as the worldwide standard for vacuum systems.

If different gate valves are used, an adapter place can also ensure coupling of the VAC.SUITCASE.

Do you have any questions about the new transport technology?

With this transport technology, the possibilities for research teams and projects are extended enormously – Adenso is available to assist you with the compilation of a suitable configuration for your new, worldwide research network!

Adenso customers network research teams in the whole world with the VAC.SUITCASE!

Construction Layout.pdf

Product page (Engl.)

A suitcase full of benefits:

• Substrate dispatch in process mode

• lightweight and easy to use

• standard VAT gate valve

• cross-system with adapter

• increased capacity utilisation possibility

• simplified research projects

• overcomes local equipment deficits

• opens up new resources in R+D